Batch Management can be applied to both process and discrete manufacturing industry. It is tightly integrated with all business processes viz., procurement, manufacturing, sales and inventory management. Some of the prominent functionalities supported as part of standard SAP batch management process are as under:

• Batch Specification / Classification - Classes can be defined for a batch and characteristic values can be entered accordingly.

• Auto Batch Creation – Batches can be configured to be automatically created as part of certain standard SAP processes.

• Batch Determination - This provides an automatic batch search technique based on pre-defined criteria. It is useful during Goods Issue and SAP condition technique is used to configure this. It also helps in searching for batches using specifications.

• Batch Status - it specifies whether the batch is active, can be used further etc.

Configuration Steps:

Step 1 – Click on the link below “specify batch level and activate status management”.

The first setting is, at what level the batch number should be unique. The default setting is as below,

The advantage of having batch unique at material level is, the batch number remains consistent during stock transfer between different plants. Next the batch status management is activated,

The advantage of having batch unique at material level is, the batch number remains consistent during stock transfer between different plants. Next the batch status management is activated, The node “initial status of a new batch” allows to set the status as “restricted” when a new batch is created. If there is no check mark against “initial status” as shown in the figure below, the stock remains unrestricted. This setting is at material type level. The check box may not be required to be set in case Quality Management is active. With QM, the stocks are anyways inspected, so putting them into restricted would increase one more step of bringing them from restricted to quality inspection stock.

The node “initial status of a new batch” allows to set the status as “restricted” when a new batch is created. If there is no check mark against “initial status” as shown in the figure below, the stock remains unrestricted. This setting is at material type level. The check box may not be required to be set in case Quality Management is active. With QM, the stocks are anyways inspected, so putting them into restricted would increase one more step of bringing them from restricted to quality inspection stock.

The node “plants with batch status management” will be required if batch level is at plant level.

Step 2 – Activate batch number assignmentThe batch number can be internally assigned or externally assignment. Depending upon the business requirement, it can be configured.

Step 3 – Creation of new batchesThe new batches can be created automatically by the system or manually vide transaction code MSC1N. To create batches automatically during certain transactions / movement types, follow the path to the following node in configuration:

The node "define batch creation for production order / process order", allows you to configure for a combination of plant and production scheduling profile. It specifies whether a batch is created automatically at production order creation or production order release or no batch creation at all. Similarly “batch creation for goods movement” controls the batch creation for each movement type. The next node controls the batch creation for each material type, as shown below.

Step 4 – Batch ValuationThis step is used to maintain batch characteristic values while creating batches in the background (automatically) or manually in the foreground. Batch characteristics are also useful when batch determination functionality is required during goods issue. The batch anyways inherits the material characteristics / class for which it is created.

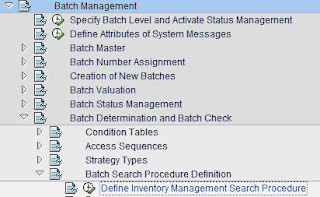

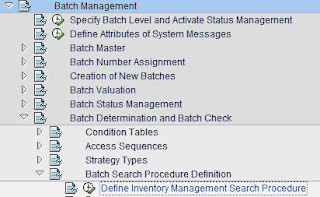

Step 4 – Batch ValuationThis step is used to maintain batch characteristic values while creating batches in the background (automatically) or manually in the foreground. Batch characteristics are also useful when batch determination functionality is required during goods issue. The batch anyways inherits the material characteristics / class for which it is created.  Step 5 – Batch DeterminationIt uses the standard sap access sequence search strategy. Over here, strategy type is like condition type in pricing. The following screen shows how to set it up.

Step 5 – Batch DeterminationIt uses the standard sap access sequence search strategy. Over here, strategy type is like condition type in pricing. The following screen shows how to set it up.

Click on the above node and the list of existing strategy types will appear.

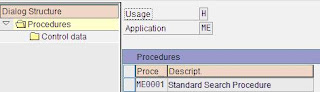

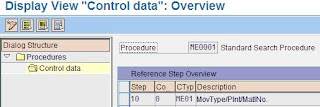

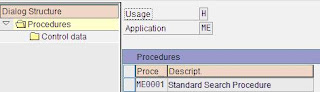

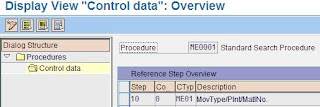

A new strategy type can be created here, preferably a copy of one of the existing strategy type. These strategy types are then used in “Batch search procedure definition” as shown below.

A new strategy type can be created here, preferably a copy of one of the existing strategy type. These strategy types are then used in “Batch search procedure definition” as shown below.

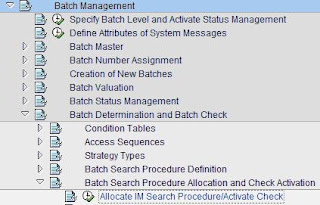

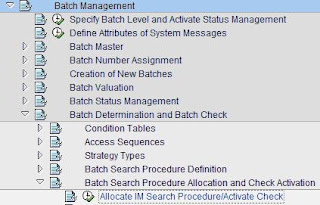

The batch search procedure configured above, now needs to be allocated to IM movement types.

Step 6 – Define Sort RulesThis step determines, as the name suggests, a rule is created to sort the batches during batch determination. This sorting happens based on the characteristics defined for the batch.

The key combination displayed above (for T Code MBC1) is as per the access sequence configured under “batch determination and batch check”.

The key combination displayed above (for T Code MBC1) is as per the access sequence configured under “batch determination and batch check”.

A new strategy type can be created here, preferably a copy of one of the existing strategy type. These strategy types are then used in “Batch search procedure definition” as shown below.

A new strategy type can be created here, preferably a copy of one of the existing strategy type. These strategy types are then used in “Batch search procedure definition” as shown below.

The batch search procedure configured above, now needs to be allocated to IM movement types.

Step 6 – Define Sort RulesThis step determines, as the name suggests, a rule is created to sort the batches during batch determination. This sorting happens based on the characteristics defined for the batch.

Step 7 – Master Data SettingIn material master, “batch management” indicatory needs to be set if the material is to be handled in batches.

The condition type / strategy type for batch determination needs to be maintained. The T Code for the same is MBC1.

The key combination displayed above (for T Code MBC1) is as per the access sequence configured under “batch determination and batch check”.

The key combination displayed above (for T Code MBC1) is as per the access sequence configured under “batch determination and batch check”.Shelf Life Expiration Date Check:

This can be enabled as per the node below.

The following screen shows how to set it up for tolerance key “PP” – Price Variance. It says that tolerance key PP is active for company code 2600 and the lower limit for tolerance is 5% and upper limit is $ 100.

The following screen shows how to set it up for tolerance key “PP” – Price Variance. It says that tolerance key PP is active for company code 2600 and the lower limit for tolerance is 5% and upper limit is $ 100. There are also situations when the invoice, though within tolerance, is entered with a large amount. It is then recommended to block the invoice to check the amount. It can also be applicable to cases when invoices do not refer to any purchase order. To activate this check, tolerance key “AN” - Amount for item without order reference and “AP” - Amount for item with order reference, need to be configured. Subsequently the following node “Activate Item Amount Check” needs to be activated.

There are also situations when the invoice, though within tolerance, is entered with a large amount. It is then recommended to block the invoice to check the amount. It can also be applicable to cases when invoices do not refer to any purchase order. To activate this check, tolerance key “AN” - Amount for item without order reference and “AP” - Amount for item with order reference, need to be configured. Subsequently the following node “Activate Item Amount Check” needs to be activated.